IOT printed-electronics sensor kit said to ease experiments with Henkel functional inks

Adhesive-provider Henkel has launched a sensor experience kit tailor-made for IOT engineering across industries. The Henkel Qhesive Solutions Sensor INKxperience Kit offers four different printed-electronics technologies that are pre-configured with hardware and software for prototyping and engineering ideation. The kit has been designed for professional engineers and enables them to quickly and efficiently explore and experiment with the technology of printed electronics for the development of IOT sensor solutions.

The broad Loctite portfolio of functional inks allows to print functional electronics circuits on foil, creating flexible circuitry for various applications, including IOT sensors. Together with its partners, Henkel enables the development of printed-electronics applications tailored for the specific properties demanded by industrial customers. The company´s inks are suitable for a broad variety of sensor technologies including water-detection sensors, self-regulating heating, pressure sensing, or printed antennas.

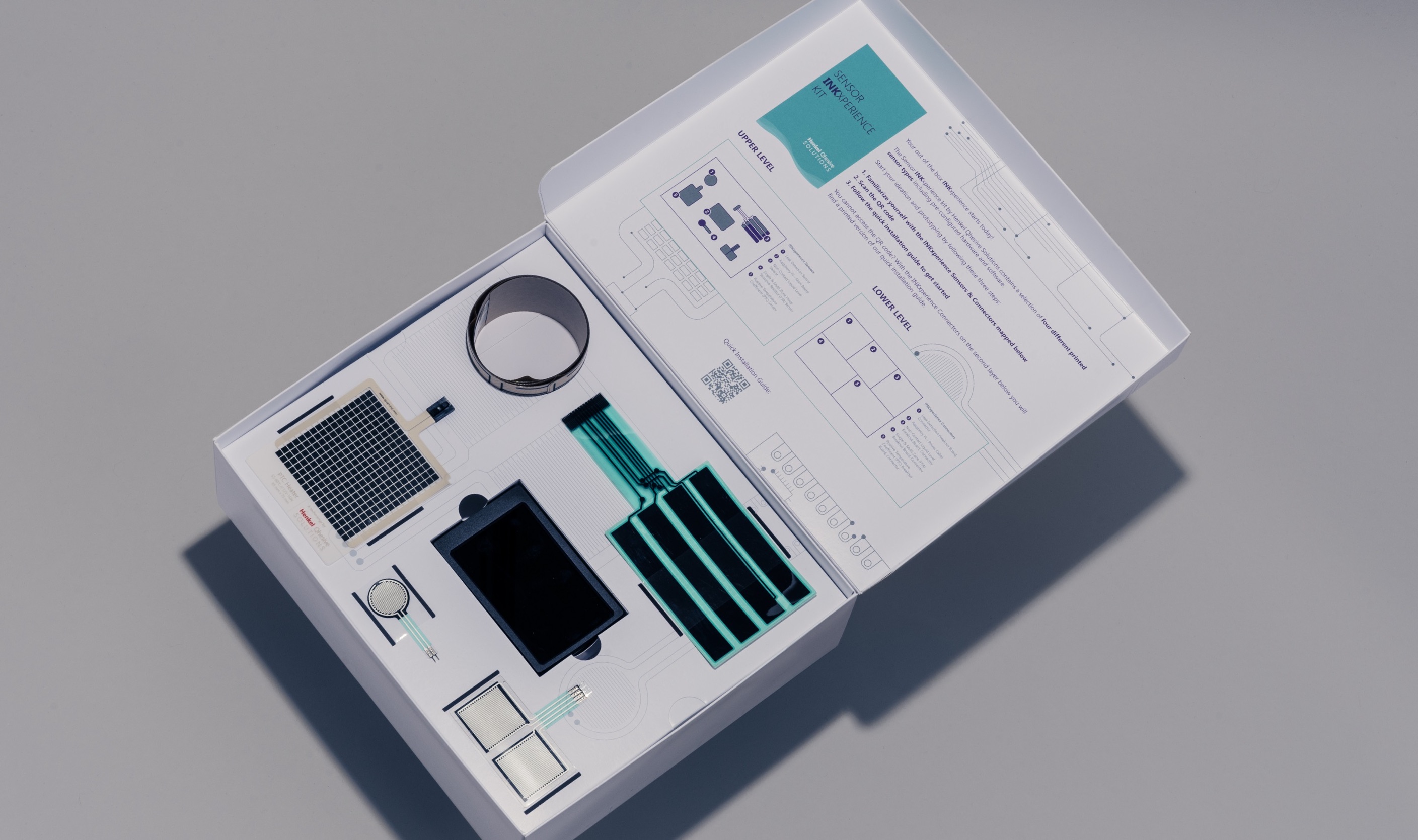

Henkel has developed the Sensor INKxperience Kit in collaboration with its partners LAIIER® and Quad Industries. To demonstrate the potentials and various functionalities of the company's inks for the development of smart-product applications, the kit contains four different technologies: a Leak Detection Sensor, a Non-Contact Liquid Level Sensor, a Positive Temperature Coefficient (PTC) Heater and a Single as well as Multi Zone Force Sensitive Resistor (FSR) Sensor, which are all reusable multiple times. The printed technologies are pre-configured with hardware and software for immediate and continuous data read-out and offer an easy set-up for the ideation of new ideas and proof concept during prototyping and the engineering process of next generation IOT sensors.

IOT engineers can use the kit to explore the possibilities printed electronics offers for the development of sensor solutions. The technology is already implemented across a variety of industrial end-application markets, ranging from building construction and building information management and modelling to logistics, transportation, smart home appliances and furniture. The printed sensor technology complements traditional sensor hardware opening-up new opportunities in intelligent surface sensor design. The application of printed surface sensor technologies combined with hardware and software enables a new scope of data collection for remote monitoring, offering benefits in terms of efficiency tracking and, in addition, a sustainable use of resources and improved product lifetime, for example maintaining the structural health of a building.