Eco-friendly NFC-tag labeling uses paper-based antenna substrate

Communication performance equivalent to products using plastic film achieved with new circuit fabrication technology and fraudulent reattachment prevented by antenna breaking when label is removed.

Tokyo-based Toppan has developed an eco-friendly near-field communication (NFC) tag labeling that uses paper material as the substrate for the antenna instead of conventional polyethylene terephthalate (PET) film. Europe is expected to be a promising market due to a high level of environmental consciousness.

In addition to reducing plastic consumption to zero by switching to paper, a new circuit fabrication technology ensures sufficient communication performance as an NFC device. Taking advantage of the properties of paper as a substrate, the NFC tag label is designed to break when it is removed, making communication impossible and thereby preventing fraudulent use due to reattachment of labels.

The value of the global NFC-tag market hit US$3.8 billion in 2020 and is expected to reach US$15.5 billion by 2030. In addition to increased use in contactless-payment systems and supply-chain management, this is driven by factors including more social distancing as a result of the COVID-19 pandemic.

NFC tag labels are predominantly produced by using metal foil to form an antenna on a plastic substrate, such as PET film. As governments and businesses advance activities to move away from the use of plastic, the market for NFC tags is seeing growing demand for replacing plastic with paper materials that have lower environmental impact. However, achieving sufficient communication performance has been challenging because the electrical resistance of circuits increases when printing methods employing conductive inks, such as widely-used silver nanoparticles, are used to form antennas on paper.

Plastic-free with communication performance equivalent to conventional products

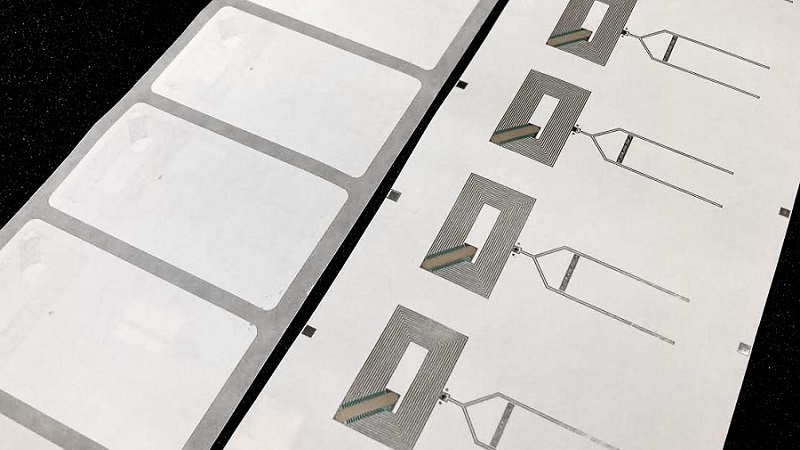

Aluminum foil with low electrical resistance is used to form an antenna on a paper substrate via a new circuit fabrication technology combining laser edge technology with a roll-to-roll web handling process. This eliminates plastic from the NFC tag while maintaining the required communication performance. If a paper substrate is used instead of a PET film substrate for a million standard size NFC tag labels (80 mm x 45 mm), consumption of plastic resin can be reduced by approximately 110 kg.

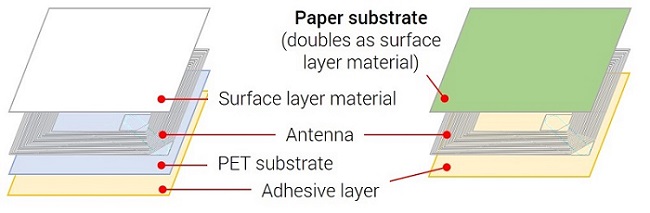

Label thickness reduced by 30% due to reduction of constituent materials

Due to a layer structure in which the paper substrate doubles as the surface layer material, the new eco-friendly NFC tag label is 30% thinner than Toppan’s existing products with PET film substrates. This means that documents or the like to which NFC tag labels have been attached do not become bulky when stacked.

Illustration of the layer structures of an NFC tag label using PET film as the antenna substrate (left) and Toppan’s new eco-friendly NFC tag using a paper-based substrate (right). © TOPPAN, INC.

*Lamination of a separate printed layer is required when applying color printing to the label surface.